Increase components lifetime, promote repair and reuse solutions and develop local repair centres

Terms of the action or commitment

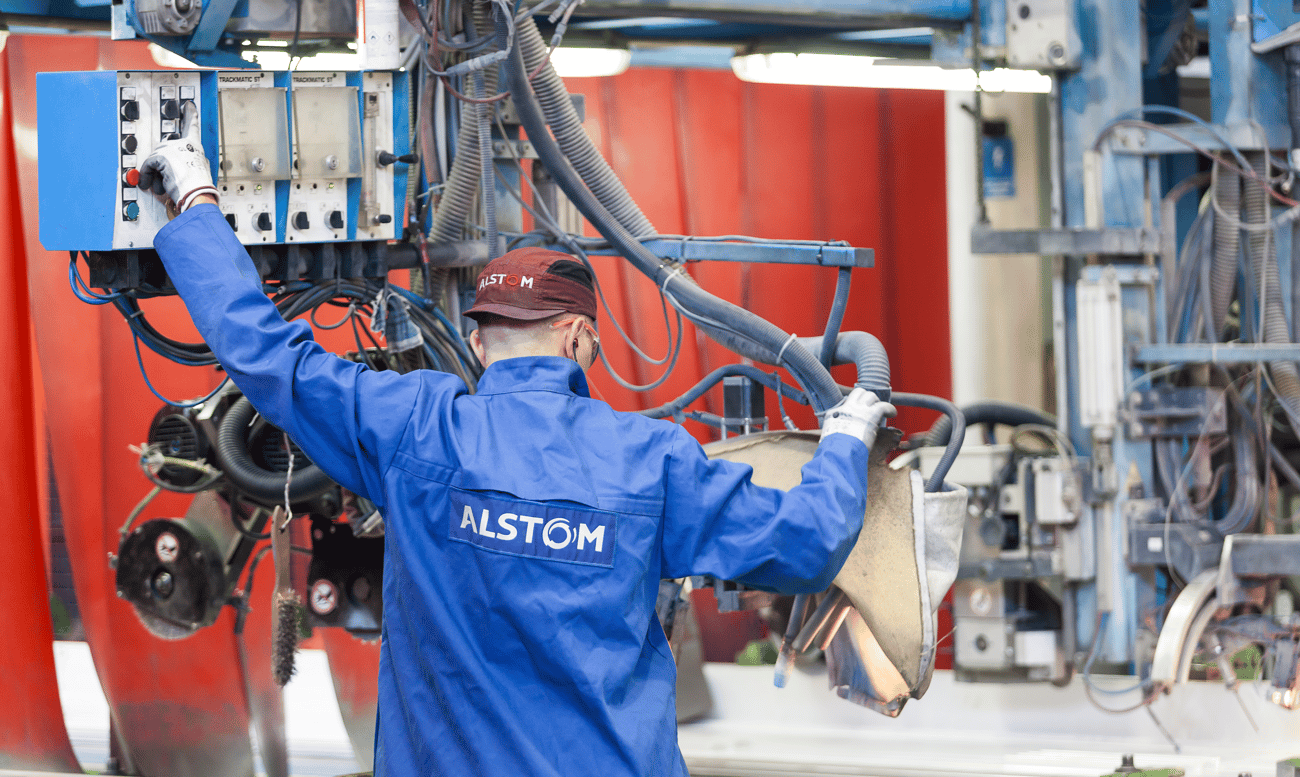

As the lifespan of a train can extend over an average of 30 to 40 years, ALSTOM offers a range of services which includes maintenance and modernization operations, making it possible to extend the lifespan of the train and the systems while improving performance.

For these activities, ALSTOM’s contribution to circular economy is based on three key actions:

– Increase the lifespan of components and optimize the use of resources – ALSTOM aims to quantify the environmental impact of a reference maintenance solution as well as the environmental benefits of its Health HubTM predictive maintenance program, to develop a system for monitoring resource consumption during maintenance and modernization phases and creating a market for second-hand spare parts for the railway sector, including dormant / obsolete parts

– Shorten repair loops, by deploying centers and promoting local repair on its maintenance and modernization sites

– Promote the repair and usage of used parts, by developing pilot projects on the company’s sites but also by developing reconditioning and take-back options with existing suppliers and reconditioners.

For these activities, ALSTOM’s contribution to circular economy is based on three key actions:

– Increase the lifespan of components and optimize the use of resources – ALSTOM aims to quantify the environmental impact of a reference maintenance solution as well as the environmental benefits of its Health HubTM predictive maintenance program, to develop a system for monitoring resource consumption during maintenance and modernization phases and creating a market for second-hand spare parts for the railway sector, including dormant / obsolete parts

– Shorten repair loops, by deploying centers and promoting local repair on its maintenance and modernization sites

– Promote the repair and usage of used parts, by developing pilot projects on the company’s sites but also by developing reconditioning and take-back options with existing suppliers and reconditioners.

Levers mobilized for circular economy (according to Ademe)

Implementation timeline

Starting year

2020

Ending year

2025

Main actors mobilized

Internal actors

Eco-design, Purchasing, Services platform, Sustainable development and CSR

External actors

Railway industry, Suppliers

Geographic area

Worldwide

Photo / Video

2022 follow-up of the action

Date of follow-up

16/05/2022

Methods of validation of the follow-up

Internal validation

Status of the action

In progress

Completed

a) Results

Achieved

Partially achieved

Not achieved

b) Numerical / Qualitative information

Cancelled

Explanations

Comparison with the projected pace in the last publications

Keeping up with the times

In advance

Delayed

Partial / Final results

In 2021, ALSTOM implemented many repairs of parts in order to be able to offer them on the second-hand market. A roadmap dedicated to the circular economy has been put in place covering design and production; maintenance and modernization; waste management and recycling; this is being rolled out gradually.